- Home

- About Us

Established in 2008, LINKDRAW is dedicated to providing quality metal injection molding services as well as top of the line manufacturing of metal powder products using a process known as MIM (powder injection molding) - a process which features less material waste, a higher size precision, and a better chemical and physical performance. It is our mission to continue using this technology in the production of the best metal part manufacturing methods for our customers.

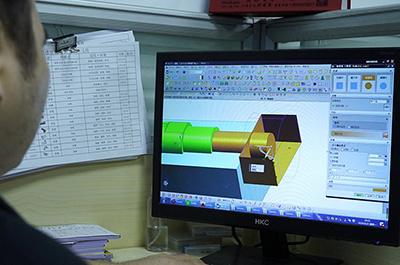

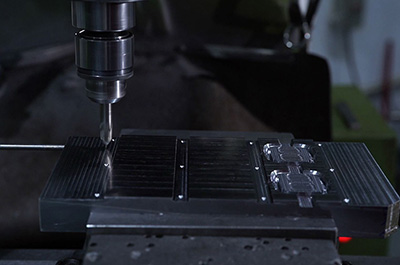

LINKDRAW is equipped with a complete set of production and processing equipment for the production of MIM molds and MIM parts. Our manufacturing equipment includes 5 CNC milling machines, 5 EDM machines, sintering furnaces, grinding machines, lathes, injection molding machines and more, ensuring our annual production capacity of 350 sets of MIM molds and 5 million MIM parts.

From design to raw material selection to mass production, our professional techniques and production team will find the right MIM solution for all customer needs, and compared to other manufacturing methods, our production processes are faster and more cost-effective.

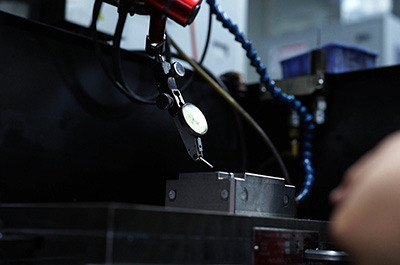

LINKDRAW is ISO9001 certified, with each step of production carried out under a strict quality control. We also use advanced testing equipment, including a 3D projector, and height measuring instruments to guarantee final product quality and put our customers first.

- No.6, Minmin Road, Jinxia community, Chang'an Town, Dongguan City, Guangdong Province

- zhuo@linkdrawdg.com

- +86-18688830044

- Mr. Zhuo