- Home

- Metal Injection Molding Service

- Capabilities

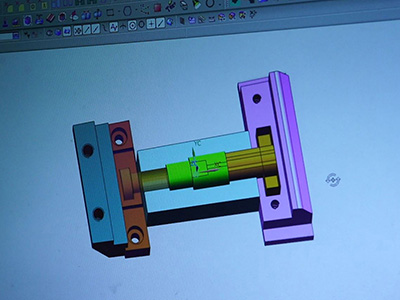

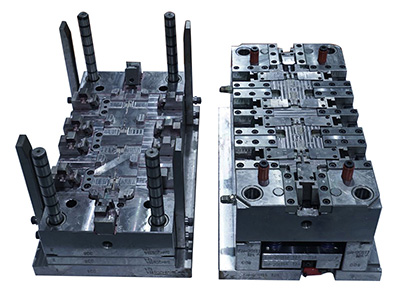

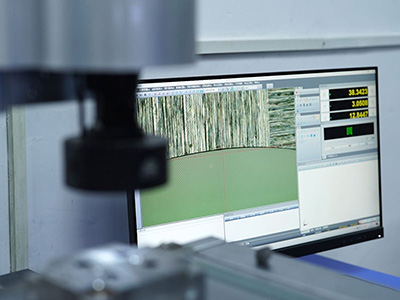

We will contact you directly, allowing the customer to participate in the manufacturing of ideal MIM parts for their needs. We are dedicated to the design and manufacturing of high quality MIM molds and parts at a customer friendly price and excellent quality. Our design methods include the use of EDM technology and CAD/CAM. With computer aided software and extensive experience in MIM manufacturing, we offer the right MIM solution for every customer. With our expertise, equipment, and technology, we manufacture our own MIM molds at a production rate of up to 350 sets of new molds a year.

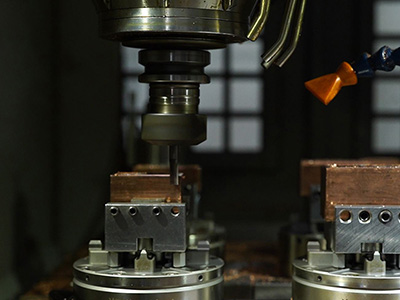

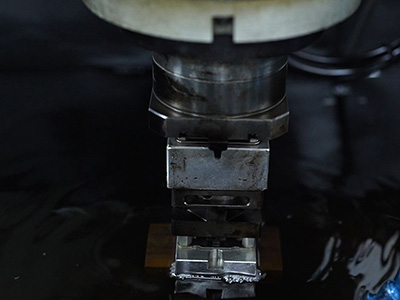

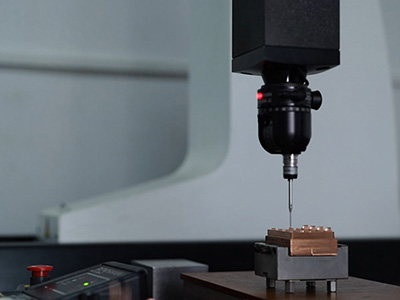

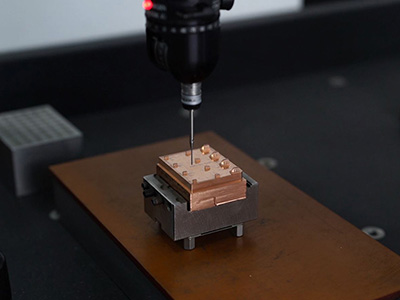

LINKDRAW is equipped with complete set of production and processing equipment for the production of MIM molds and MIM parts. Our manufacturing equipment includes 5 CNC computer gongs, 5 EDM equipment pieces, a degreasing furnaces, small diameter grinding machines, punch grinders, lathes, milling machines, injection molding machines and more. All equipment is designed to efficiently complete a variety of processing steps, including cutting, sintering, injection molding, grinding, and more.

MIM surface treatment methods include deburring, sand blasting, anodizing, painting, printing, electroplating, mirror polishing, blackening, and powder coating. We provide all of these options in our own factory using our own equipment, ensuring an excellent quality management.

- No.6, Minmin Road, Jinxia community, Chang'an Town, Dongguan City, Guangdong Province

- zhuo@linkdrawdg.com

- +86-18688830044

- Mr. Zhuo